Can A Vice Grip Tool Be Repair

Gunkhole Cover Snaps Repair

the Correct Tools for the Job!

Highlights of Boat Embrace Snaps Repair:

- The DIY Boat Snap Toolkit Essentials

- Tips for Installing Boat Snaps in Canvas

- Tips for Installing Screw Studs

- Tips for Boat Snaps Repair

- Other DIY Repair Items

DIY Gunkhole Cover Snaps Repair Toolkit

Gunkhole Cover Snaps Repair Tools:

Snap setter

Sharp scissors

Sharp pencil

Chalk

Apartment head screwdriver with narrow ¼" tip

Hammer or mallet

Block of woods – finish grain

Cobalt or titanium drill bits ane/8", 9/64", 5/32", 3/16"

Plastic Wall Anchors eight-x x 3/iv" for enlarged holes in the fiberglass

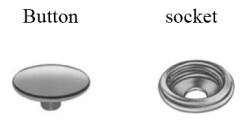

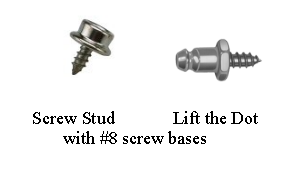

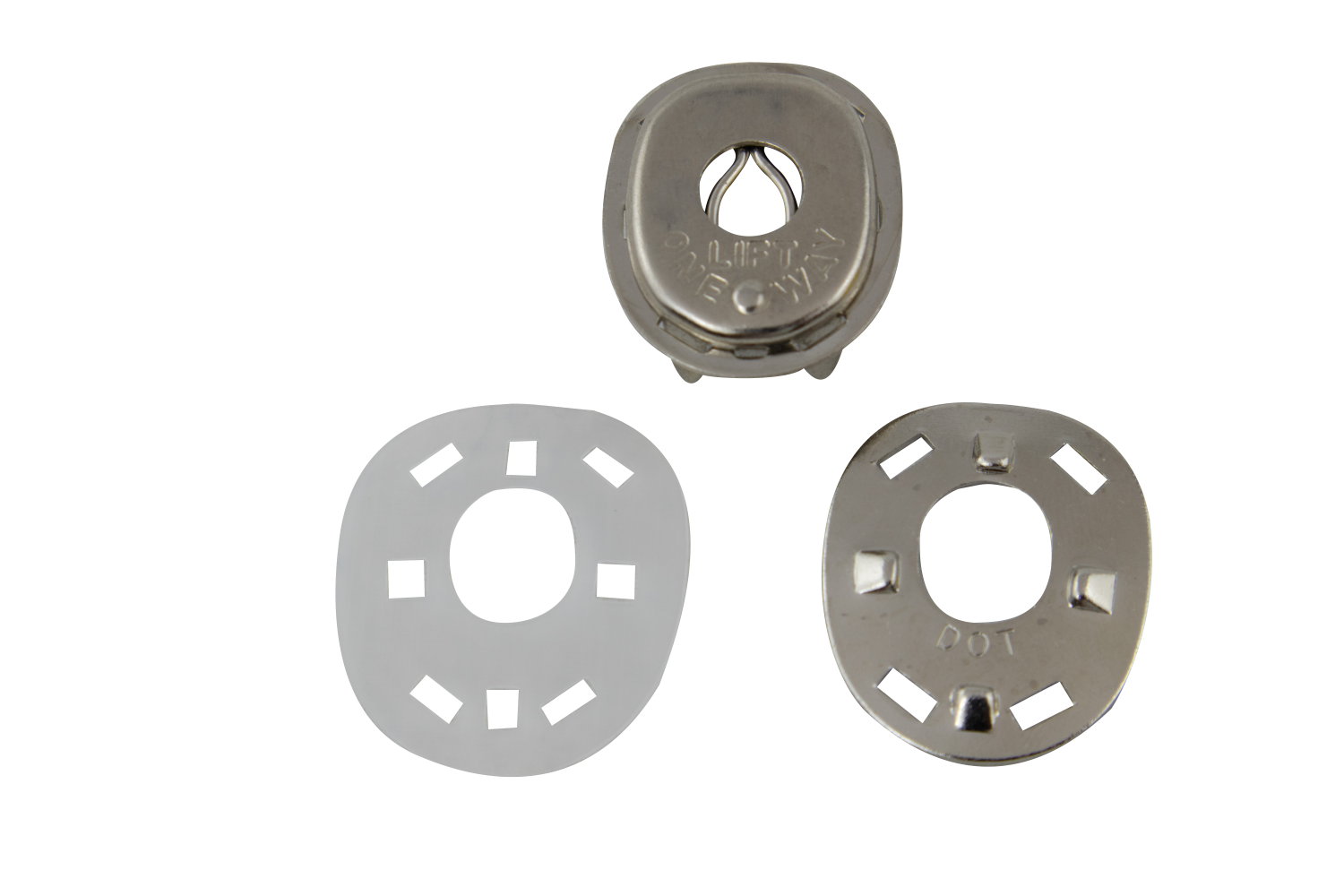

The most common type of boat snaps y'all volition want to install for boat cover snaps repair are Dot®Fasteners.

Dot Fasteners

Dot Fasteners

It is a mutual problem for boat snaps to come apart on the sail due to crimping failure.

An equally troublesome problem is when boat encompass snaps really pull through the canvas from a tear or an enlarged hole in the canvas.

This always requires a patch to be sewn on before setting a new snap for your boat cover snaps repair.

See how to sew together on a patch on our boat comprehend repair page.

| | |

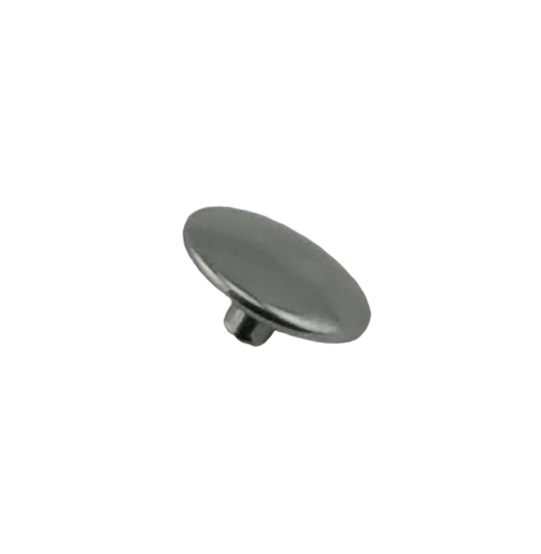

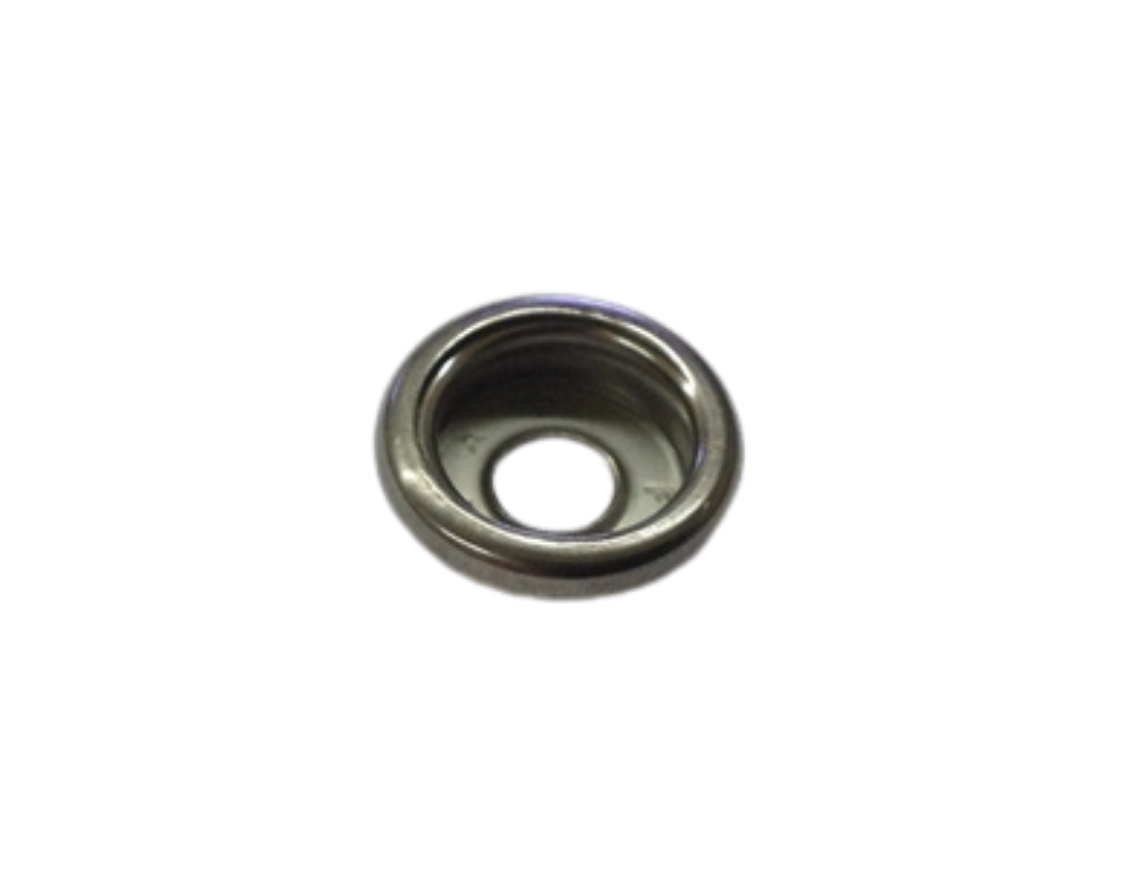

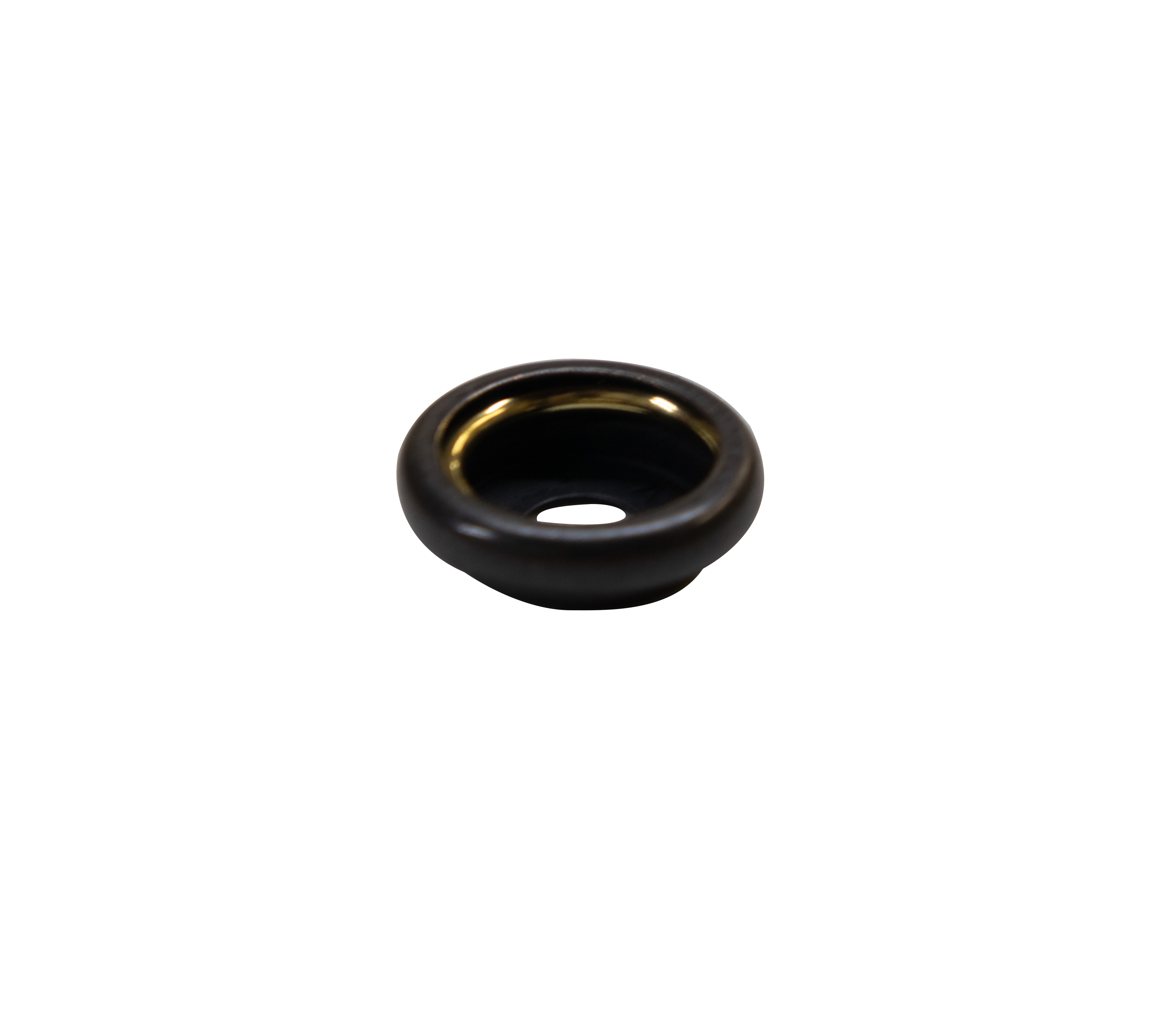

| Stainless Steel Durable Button | Stainless Steel Durable Socket |

| Black Durable Button | Black Durable Socket |

Installing Dot and Fasnap Boat Snaps in Sail

Professionals primarily use the Pres-n-Snap® tool built past Hoover to gear up snaps. Information technology is costly, but the press way tools are your best option if you lot desire a professional person crimp for your boat cover snaps repair.

| Pres-n-Snap® Tool | |

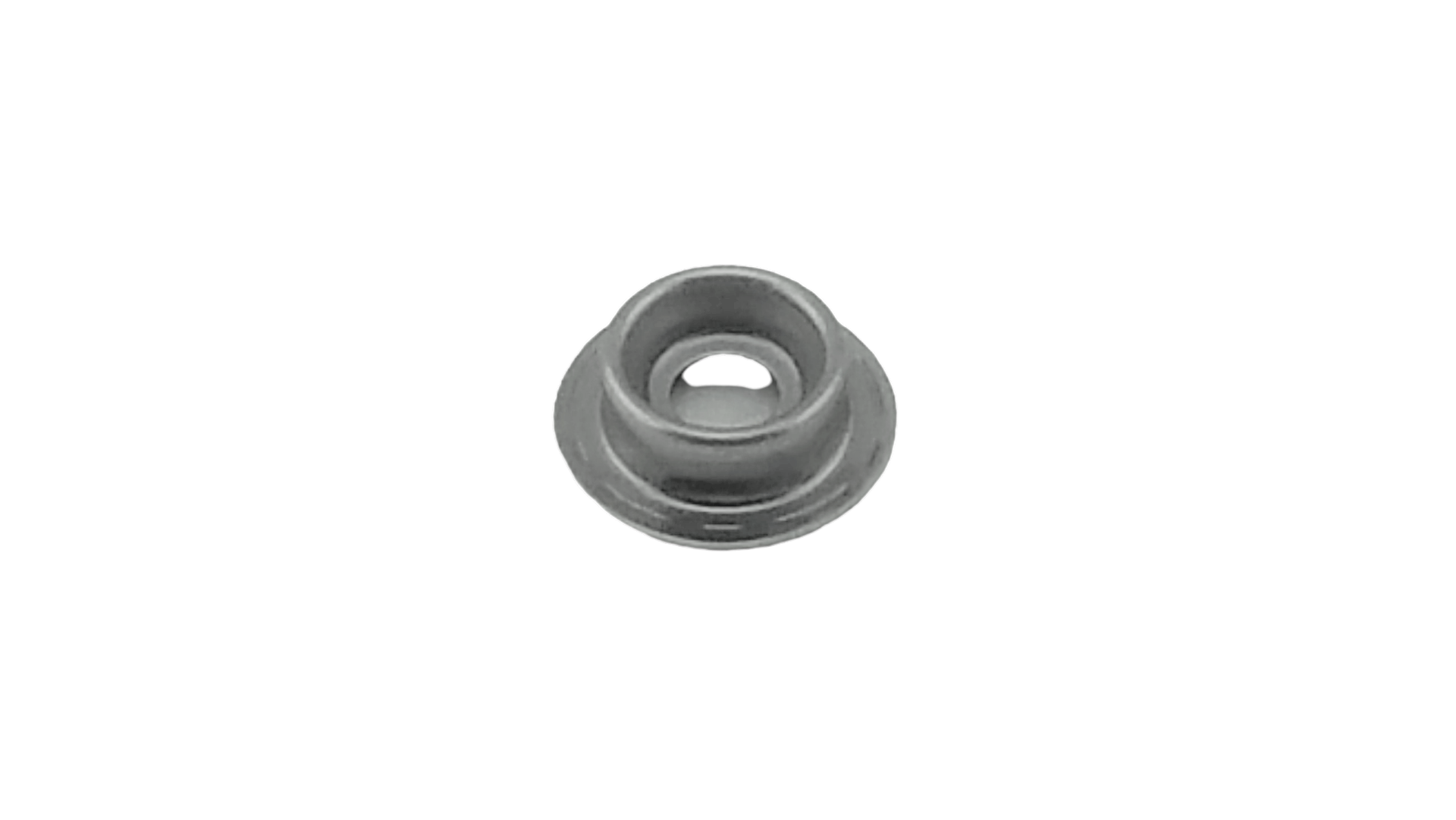

Boat embrace snaps can be prepare with an anvil manner fix tool like the heavy duty anvil we sell pictured below. The quality of anvil style tool will vary the quality of the crimp. This one will exercise a fine job for your gunkhole cover snaps repair along with the stainless steel snaps we sell. Information technology volition prepare both cap and socket (Female) or eyelet and stud (Male) but by flipping information technology over.

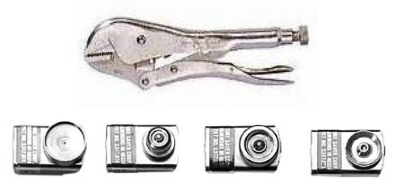

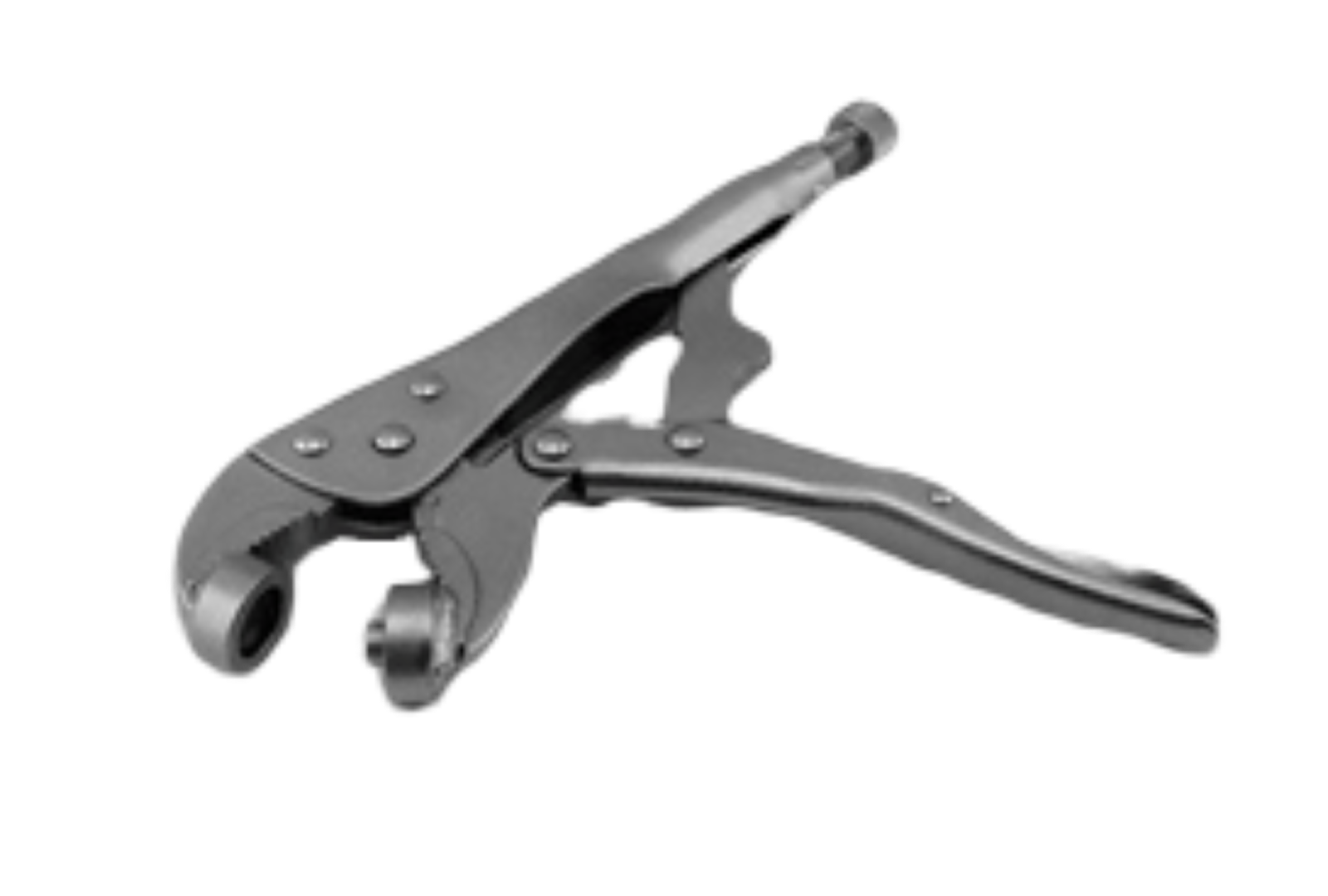

The vice grip tools shown below are a little quicker and no hammering will be required for your boat cover snaps repair.

The first photo below shows the Time Saver vice pliers which do a adept chore with the nickel/brass snaps, but the stainless steel might exist a bit much for the snap-on dies shown here. It'south also easy to lose the dies.

Time Saver tools does sell kits that include nickel/contumely snaps for your gunkhole cover snaps repair.

Deport in mind that even though we apply stainless steel snaps in our shop, nickel/brass snaps have been used for many years by fabricators and many still employ them. They are perfectly acceptable for any climate when doing your boat embrace snaps repair.

The second photo is the style of vice grips nosotros sell. The difference in these pliers is that the dies are welded on. The welded on dies are for the cap and socket snap which is the most common snap installed on boat canvass.

Caps and sockets mate with the screw-in studs ordinarily screwed into fiberglass boats everywhere. However, buying this tool leaves you without the dies used for installing the eyelet and stud side of the snap.

DIY Tip: The vice grips in this kit are bigger than boilerplate, then don't buy the dies by themselves because they may not fit on the tool you take at home for your boat cover snaps repair.

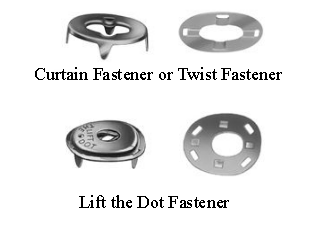

Installing Curtain/Twist Fasteners & Elevator-The-Dot Fasteners

Professionals install these fasteners using an expensive hand punch tool, and this method is non practical for the DIY boater.

The curtain fastener (twist fastener) and the Elevator-The-Dot fasteners all come with 2 parts – the 4 prong male top side and the female backing plate which sandwiches the material between itself and the male side. The prongs crimp down and agree tight to the backing plate. Both of these boat cover snap fasteners can be installed with a little patience and without expensive tools.

| | |

| | |

Here is a what you'll need for this job:

- Block of wood with the end grain upwardly

- Apartment nose screwdriver 1/8" - 1/4" wide

- Hammer

- Sharp pair of pair of scissors

- Chalk

- Sharp pencil for marking

1. Commencement brand certain the canvas where the boat snap is beingness installed is reinforced so the snap will not rip through the fabric. If you need to repair the canvass first, do so.

2. Mark where the fastener will become in your comprehend.

three. Chalk the tips of the prongs on the male side of the fastener.

4. Center the chalked prongs over your original snap mark on the fabric and touch the tips of the prongs to the cloth to transfer the chalk marks.

5. Flip your pronged male fastener over, then position and mark the oval center hole that is between the 4 prongs.

6. Putting a block of woods under your fabric, utilize your tiny tip apartment head screwdriver and tap with a hammer to dial the holes for your prongs.

7. Next use the same technique to start a airplane pilot hole in the heart, finishing with a pair of sharp scissors and carefully cut the oval pigsty in the fabric. Try not to cut the eye pigsty too large.

viii. Insert your male drape or LTD fasteners into the hole and crimp the prongs downward over your backing plate using a small hammer on the back side.

Y'all have now successfully installed a prissy, new fastener and completed your boat encompass snaps repair!

Installing a spiral stud into your boat

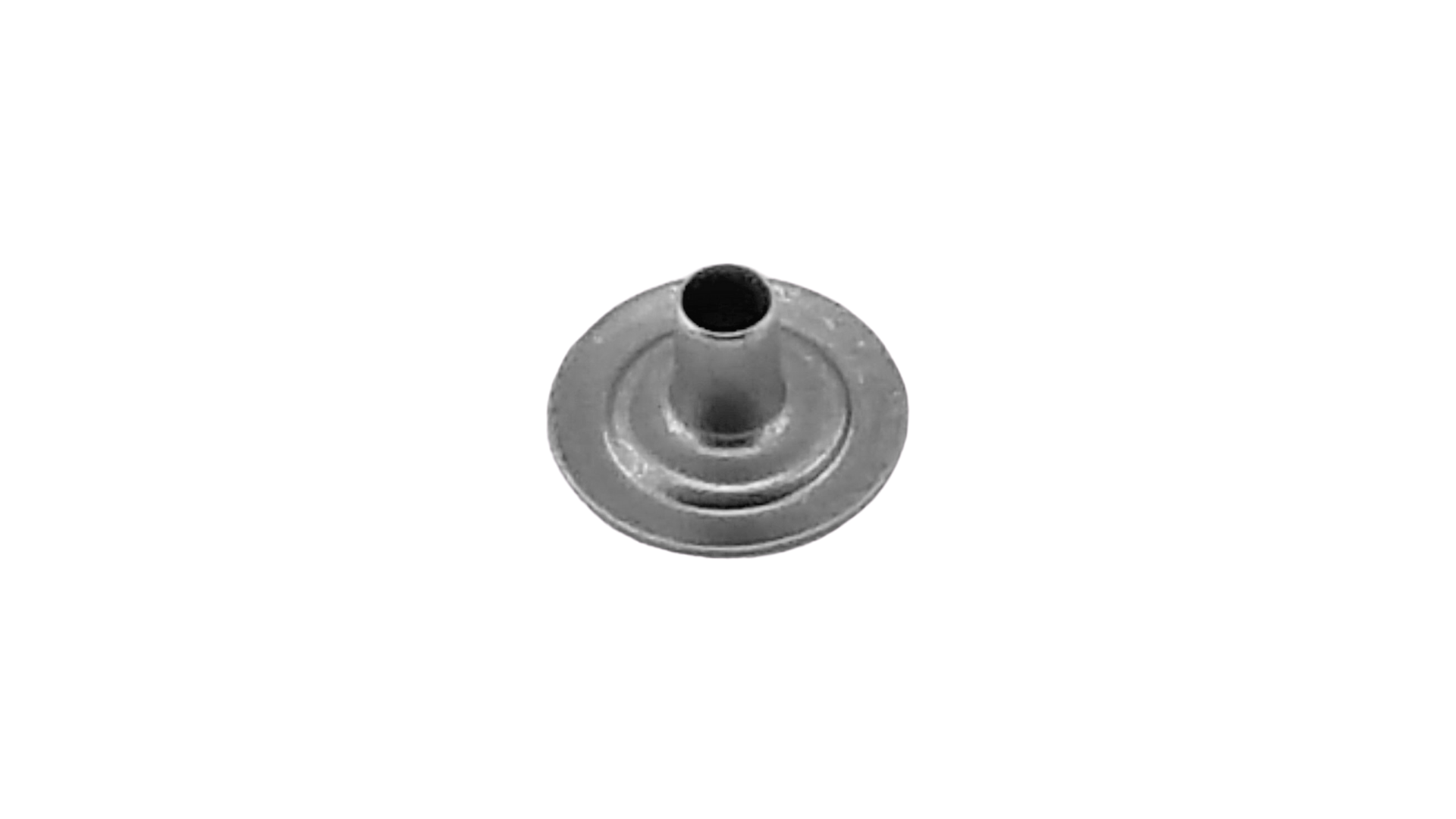

Basic screw studs and Lift the Dot studs have a #8 screw base

| | |

| | |

These require either a 1/viii" or 9/64" drill fleck

E'er start with an 1/8 inch drill bit to test the thickness of the fiberglass in your boat.

After you lot drill any hole in fiberglass, yous will need to countersink the hole. This just ways that you need to clean away the sharp edges of fiberglass from the opening of the hole.

You can use a #ii Phillips head bit in your drill to countersink the superlative of the hole if you don't have a countersink.

Only spin the Phillips caput in the drilled pigsty while asserting pressure and you lot volition clear abroad a nice opening as shown in the photo below.

Countersink Hole

Countersink Hole

Now exam screw by hand your #8 screw stud or your Lift-the-Dot®stud into your fiberglass pigsty, applying firm downward pressure as you twist. The downward force per unit area helps limit the maybe of dandy your fiberglass.

As you go along, if you lot feel too much resistance and the fiberglass feels too thick,stop! You are in danger of twisting off the screw, stripping your screw head, or even worse cracking the fiberglass.

At present switch to your 9/64 inch drill bit and re-drill the hole again. You're screw should now go in snugly, only with less resistance.

If you feel the need, you tin can drill all of your holes with the ane/viii inch drill fleck and examination, you lot can e'er go back and drill once more with your 9/64 inch drill chip.

This will help you go a feel for drilling into the varying thicknesses of your boats fiberglass.

Installing screw studs into aluminum

You tin install a spiral stud into thin aluminum using the right drill bit and Phillips head bit. Aluminum is usually found on your windshields and pontoon railing.

I use a 9/64 drill scrap for aluminum. Over again, y'all can examination your screw on this size hole and if the aluminum is too thick and you lot meet with too much resistance, move upwards to a 5/32" size.

If you are using pop rivets with a dot stud, a 1/viii" scrap should be right.

Be very conscientious when drilling into windshield metallic. In 30 years of doing this, I did break a side windshield and getting the glass replaced was a huge hurting. Then if you are unsure of where your glass lays inside the metal windshield, get help or hire a professional.

How to repair boat cover snaps

If your boat snaps take pulled out of the fiberglass and left an enlarged hole, y'all take a couple of different choices.

First selection would exist to attempt a screw stud with a #10 screw base and run across if it is big enough to hold in the fiberglass.Go along the smallest size available on your boat which should be a viii-10 x 3/4".

| | |

| | |

If the hole is still too large you lot tin can use a plastic drywall anchor like this 1. They do come up in varying sizes.

Use a 3/16" drill bit for the plastic ballast and add a little 4200 marine adhesive before y'all insert the anchor. We similar the 4200 over the 5200 because information technology stays just a little flexible. You lot should meet some resistance when tapping it into the hole, but not plenty to brew the plastic ballast.

Once it is inserted in the hole, you can then secure your screw into the ballast. Y'all should now have a solid hold.

Repairing your own spiral studs and boat cover snaps is easy and something whatsoever DIY guy or gal can exercise for themselves. So go for it and good luck!

DIY Repairs

Merely in case you need a few other items for your DIY repairs, take a await at our boat encompass repair kit and thread products below. Nosotros've as well added Durable Dot® Eyelets and Studs for your convenience. We accept many boat canvas materials to choose from as well. Run into the link below to take a look!

| | | |

| | Too run across our boat canvas fabric selection here . | |

| | | |

| | | |

| | |

| Stainless Steel Durable Eyelet | Stainless Steel Durable Stud |

| Black Durable Eyelet | Black Durable Stud |

our Other EZ-Xtend Boat Attachment products:

EZ-Xtend Boat Zippers

EZ-Xtend Boat Rail

EZ-Xtend Drip Shields

C.South.Osborne is a registered trademark of C.Southward.Osborne & Co.

Pres-n-snap is a registered trademark of Hoover products

Lift-The-Dot is a registered trademark of Dot Fasterners

Please come up visit me at Cover Daughter Marine Canvas & Upholstery to see some of our awesome work!

Can A Vice Grip Tool Be Repair,

Source: https://www.canvas-boat-cover-and-repair-advisor.com/boat-cover-snaps-repair.html

Posted by: murphycalat1937.blogspot.com

0 Response to "Can A Vice Grip Tool Be Repair"

Post a Comment